Geotechnical Investigations

Determining a new East African pipeline route for TOTAL

The project entailed geotechnical investigations for a Central Processing Facility (CPF) in Uganda and a pipeline to transport oil from the CPF 1100 kms to Tanga on the coast of Tanzania.

Lesotho LHDA Dam Investigations - Oxbow and Senqu

The project, which incorporates a geotechnical investigation and Lugeon testing for a potential dam site is located at two remote sites, one at Senqu B and the other at Oxbow.

East London Harbour Quay Wall

The project required that we drill 6 holes (HQ3 size), with SPT’s, Shelbey’s and Shearvane testing, half a meter out into the sea from the Quay edge.

Geotechnical Investigations for AECOM | Stellenbosch, Western Cape, SA

In June 2020 AECOM commissioned Geomech Africa (Pty) Ltd. to assist with the drilling of four geotechnical boreholes, a total of 70 meters, at the abutments of the existing Distillery Road Bridge crossing the Plankenberg River near Bosman’s Crossing in Stellenbosch, Western Cape. The existing bridge is the only access to Bosman’s Crossing. Due to its narrow dimensions, the bridge width needs to be widened to accommodate the increase of traffic.

Reverse Circulation Drilling | Letšeng Diamond Mine

“The Geomechanics drill team drilled 3 354 meters using the Reverse Circulation drill method.”

What is Reverse Circulation Drilling? Reverse Circulation drilling, or RC drilling, is a specific method of drilling which makes use of dual wall drill rods. These drill rods are a combination of an outer drill rod and an inner tube. With RC drilling, the rock is fragmented into chips by use of a piston that delivers rapid impacts to the stem of the hammer.

Road Interchange, Paarl

CPTu testing for a road interchange in the Paarl area. The project entailed 12 CPTu’s, with augering through the hard layers, to a total depth of 20m.

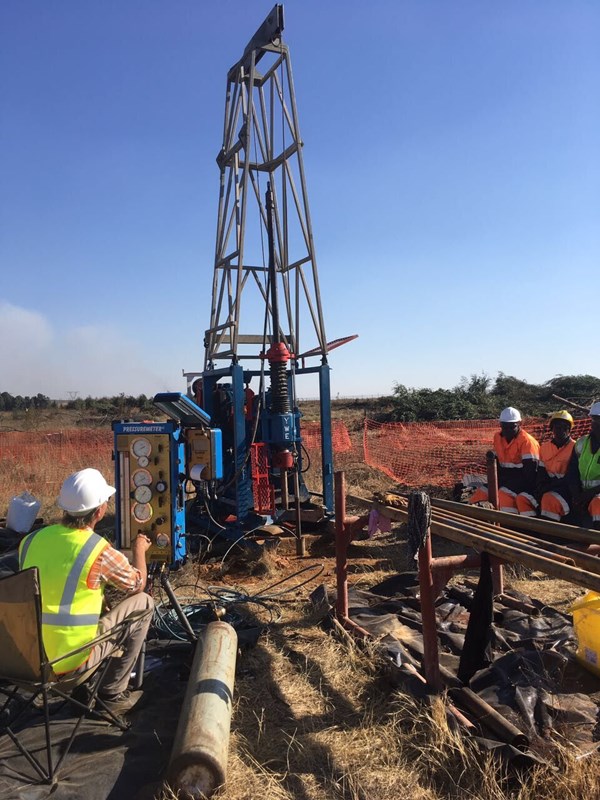

Khanyisa Power Station

The Apageo Pressure Meter test and other In-Situ tests were done to determine the soil characteristics to be used for assessment of excavation methods and for detailed design of foundations, ground improvement and earthworks.

Fufu Hydropower Project, Malawi

The Ministry of Energy and Natural resources of Malawi commissioned Geomechanics to undertake a geotechnical survey of two potential locations for hydroelectric power stations, one in the north and one in the south of Malawi.

CPTu testing to establish the profile of mine's orebodies

Geomech Africa was recently contracted to help Tronox Fairbreeze mine establish certain geotechnical properties of their orebodies as a basis for future mine expansion.

Exploration Drilling

AEL Sonic coring project at Modderfontein

Geomechanics was commissioned to determine the extent of contamination of explosive material in the ground. The Geo-601 Comacchio combination drill rig was converted to drill remotely to reduce the risk of injury to staff from drilling into unexploded ordinance.

Black Rock

Largest underground drilling contract to date was for Assmang’s Black Rock mine operations project in the Northern Cape which was completed with a flawless safety record and uncompromised commitment to quality assurance and environmental project aspects.

Geomech Africa helps Foskor to optimise its North and South pits.

Geomech Africa recently completed a 3-month geotechnical survey for Foskor Mining Division in the Limpopo Province of South Africa. The objective of the project was to identify the continuity of the rock to help optimse the North and South pits

Drilling in sands for Rio Tinto

Sonic drilling for Rio Tinto ’s Richards Bay Minerals sands project at the RBM site near Richards Bay. Geomech Africa uses the SDC 450-24 sonic drill rig from Canada to drill the required deep boreholes in mineral sands.

Wadrift Dam Project

Geomechanics was contracted to do an investigation for siting a holding dam and a series of boreholes at Wadrift.

GeoGroup Companies help Exxaro Secure the Safety of its New Lakeside Towers Development

The New Exxaro’s Lakeside Towers Office Development was developed over a dolomite rock formation. The dolomite formation is renowned for developing sinkholes and this poses a potential risk to the safety of structures built upon them and hence the people within those structures.

Vibrating Wire Piezometers

Tenke Fungurume Mine Project DRC Terra Monitoring (Pty) Ltd. was appointed by Golder Associates Africa (Pty) Ltd. to install eight Vibrating Wire Piezometers VWP in the North Embankment, North Saddle Embankment and Spillway Embankment of the TSF tailing dam.

Jack-up barge

Geomechanics CEO Dave Rossitter designed, and sister company Geostruct custom built, a jack-up barge that can be used to do geotechnical drilling surveys in up to 8m of flowing water. The self-propelled barge is used as a platform for the drill rig and crew for surveying the ground conditions in rivers and dams.

Track Mountings

GeoStruct manufactures the track mountings for many uses. GeoGroup uses them for its drill rigs

Plot 28 Central Road

Sunrella, Lanseria

Gauteng

South Africa

Tel. +27 (0)11 966 7760

Fax. +27 (0)86 663 3896

Email. info@geogroup.co.za