Sonic Drilling for Geotechnical Investigations

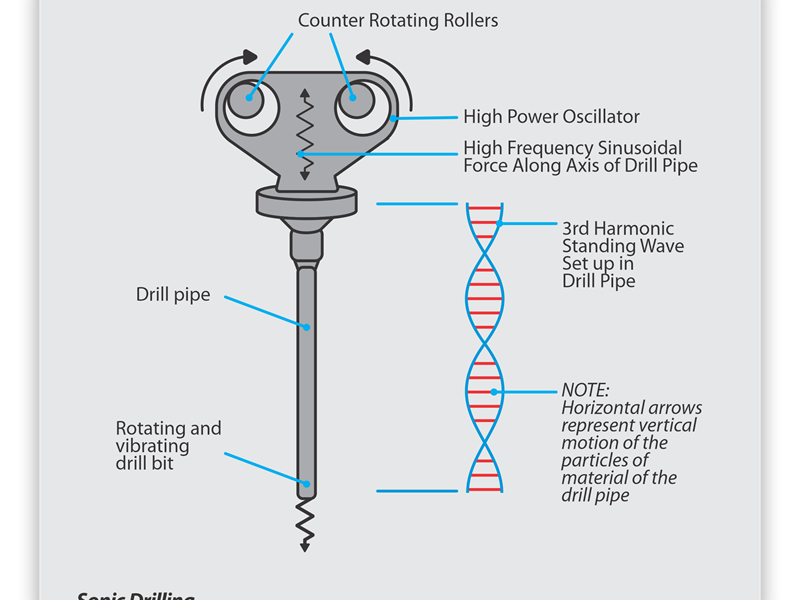

Sonic is an advanced method of drilling which uses a high-frequency energy known as an oscillation that is generated inside the Sonic head. During drilling, the high-frequency oscillation is transferred down the drill string to the bit face at various Sonic frequencies (0hz to 150hz). Simultaneously rotating the drill string (Max 90rpm) evenly distributes the energy and impact at the bit face.

Oscillation frequencies are focused from the drill head to the drill string using a pneumatic system allowing for the efficient transmission of the energy from the drill head to the drill string. This allows for maximum sample preservation and recovery.

Sonic drilling is a relatively new drilling method and has quickly become a popular choice for geotechnical investigations. It offers several advantages over traditional drilling methods, such as rotary core and percussion drilling. One of the main advantages of sonic drilling is that it is more efficient by drilling up to 2-3 times faster and it uses limited amounts of drill fluids. Sonic drilling can drill through formations much faster than traditional drilling methods. The fluidization of the thin layer immediately adjacent to the length of the drill string, results in a vast reduction in friction and thus increasing penetration rates.

Another advantage of sonic drilling is that it causes less disturbance to the surrounding formations. This is because the high-frequency oscillations do not create as much heat or vibration as the rotating bit or hammering action used in traditional drilling methods. This is an important factor in geotechnical investigations, as it helps to preserve the integrity of the sample.

In addition to its advantages, sonic drilling also has some disadvantages. One of the main disadvantages is that it is more expensive than traditional drilling methods. This is because the equipment required for sonic drilling is more complex in design and manufacture which makes it more expensive. Another disadvantage of sonic drilling is that it is not as well suited for drilling through very hard rock.

Overall, sonic drilling is a versatile and efficient drilling method that is well-suited for a wide range of geotechnical investigations.

Here are some of the specific applications of sonic drilling in geotechnical investigations:

- Site characterisation: Sonic drilling can be used to characterise the subsurface soil conditions.

- Environmental investigations: Sonic drilling can be used to investigate the subsurface for environmental contaminants. This information can be used to assess the risk of contamination and to develop remediation plans.

- Mineral exploration: Sonic drilling can be used to explore for mineral deposits. This information can be used to identify potential mining sites and to assess the economic viability of a mining project.

The GeoGroup, based in South Africa, specialises in sonic, percussion and rotary core drilling for the geotechnical investigations field. In the last decade, they have focused on growing the Sonic field within Southern Africa. They currently have 3 sonic rigs in various configurations with dual-head systems which include both a sonic drill head as well as a conventional rotary core drill head. This allows for an easy transition from sonic drilling to rotary core as the formations require it. These rigs are also equipped with automatic SPT hammers for In-situ geotechnical testing as required.

In addition to the sonic drilling equipment, GeoGroup hosts an extensive fleet of drill rigs for both geotechnical investigations and exploration drilling purposes. The group has been in operation since 1989 and has over 34 years of drilling experience. They have branches in Uganda, Botswana, and Sweden.

To explore from African Mining Insight, visit: Sonic Drilling for Geotechnical Investigations

In addition to the sonic drilling equipment, GeoGroup hosts an extensive fleet of drill rigs for both geotechnical investigations and exploration drilling purposes. The group has been in operation since 1989 and has over 34 years of drilling experience. They have branches in Uganda, Botswana, and Sweden.

To explore from African Mining Insight, visit: Sonic Drilling for Geotechnical Investigations

Plot 28 Central Road

Sunrella, Lanseria

Gauteng

South Africa

Tel. +27 (0)11 966 7760

Fax. +27 (0)86 663 3896

Email. info@geogroup.co.za